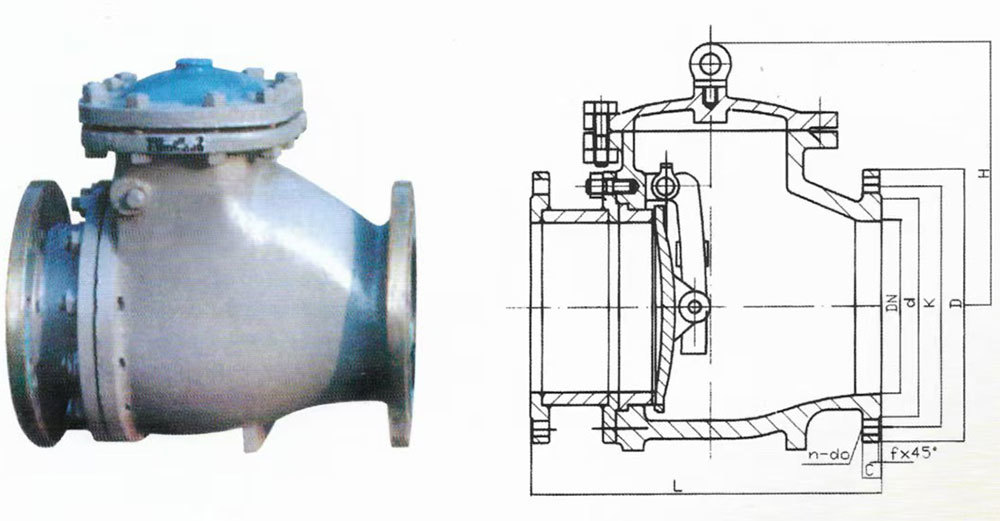

PH series non-return valve with strainer

Category:

Check valve

Keywords:

PH series non-return valve with strainer

Description

This product is mainly suitable for conveying slurry, mortar, sewage, and ash slag mixtures in mining, metallurgy, power, chemical, and sewage discharge industries with pressures not exceeding 6.4 MPa and operating temperatures ≤100℃, serving as a check valve.

Performance Specifications:

|

Product Model

|

Nominal Pressure |

Sealing Test Pressure |

Strength Test Pressure |

Operating Temperature |

Applicable Medium |

|

PH44H-10C |

1.0 |

1.1 |

1.5 |

≤120°C |

Slurry |

|

PH44H-16C |

1.6 |

1.76 |

2.4 |

||

|

PH44H-25 |

2.5 |

2.75 |

3.75 |

||

|

PH44H-40 |

4.0 |

4.4 |

6.0 |

Main Component Materials of the Slag Discharge Check Valve:

|

Component Name |

Material |

||||

|

10C |

16C |

25 |

40 |

64 |

|

|

Valve Body and Valve Cover |

WCB |

||||

|

Valve Seat |

WCB with 85 Chromium Manganese overlay weld |

||||

|

Gate Valve |

WCB+85 Chromium Manganese overlay weld |

||||

|

Rocker Arm |

2Cr13 or 1Cr18Ni9Ti |

||||

Main Connection Dimensions of the Slag Discharge Check Valve

|

Dimensions (mm)

|

D |

K |

d |

D1 |

f |

F1 |

b |

L |

Z-d0 |

H |

W (kg) |

|

|

Nominal |

||||||||||||

|

Nominal Diameter DN |

||||||||||||

|

Pressure (MPa) |

||||||||||||

|

1.0C |

100 |

220 |

180 |

156 |

3 |

3 |

3 |

22 |

292 |

8-φ18 |

270 |

63 |

|

125 |

250 |

210 |

184 |

184 |

3 |

184 |

22 |

330 |

8-φ18 |

280 |

80 |

|

|

150 |

285 |

240 |

211 |

211 |

3 |

211 |

24 |

356 |

8-φ18 |

290 |

120 |

|

|

200 |

340 |

295 |

266 |

266 |

3 |

266 |

24 |

495 |

8-φ22 |

345 |

200 |

|

|

250 |

395 |

350 |

319 |

319 |

3 |

319 |

26 |

622 |

12-φ22 |

412 |

250 |

|

|

300 |

445 |

400 |

370 |

370 |

4 |

370 |

26 |

698 |

12-φ22 |

468 |

320 |

|

|

350 |

505 |

460 |

429 |

429 |

4 |

429 |

26 |

787 |

16-φ22 |

524 |

400 |

|

|

400 |

565 |

515 |

480 |

480 |

4 |

480 |

26 |

900 |

16-φ26 |

600 |

517 |

|

|

450 |

615 |

565 |

530 |

530 |

4 |

530 |

28 |

918 |

20-φ26 |

670 |

610 |

|

|

500 |

670 |

620 |

582 |

582 |

4 |

582 |

28 |

978 |

20-φ26 |

750 |

705 |

|

|

1.6C |

100 |

220 |

180 |

156 |

156 |

3 |

156 |

22 |

292 |

8-φ18 |

270 |

63 |

|

125 |

250 |

210 |

184 |

184 |

3 |

184 |

22 |

330 |

8-φ18 |

280 |

90 |

|

|

150 |

285 |

240 |

211 |

211 |

3 |

211 |

24 |

356 |

8-φ22 |

290 |

130 |

|

|

200 |

340 |

295 |

266 |

266 |

3 |

266 |

24 |

495 |

12-φ22 |

345 |

210 |

|

|

250 |

405 |

355 |

319 |

319 |

3 |

319 |

26 |

622 |

12-φ26 |

412 |

260 |

|

|

300 |

460 |

410 |

370 |

370 |

4 |

370 |

28 |

698 |

12-φ26 |

468 |

330 |

|

|

350 |

520 |

470 |

427 |

429 |

4 |

429 |

30 |

787 |

16-φ26 |

524 |

415 |

|

|

400 |

580 |

525 |

480 |

480 |

4 |

480 |

32 |

900 |

16-φ30 |

600 |

532 |

|

|

450 |

640 |

585 |

548 |

548 |

4 |

548 |

34 |

918 |

20-φ30 |

670 |

625 |

|

|

500 |

715 |

650 |

609 |

609 |

4 |

609 |

36 |

978 |

20-φ33 |

750 |

720 |

|

|

2.5 |

100 |

235 |

190 |

156 |

156 |

3 |

156 |

24 |

356 |

8-φ22 |

270 |

65 |

|

125 |

270 |

220 |

184 |

184 |

3 |

184 |

26 |

400 |

8-φ26 |

280 |

95 |

|

|

150 |

300 |

250 |

211 |

211 |

3 |

211 |

28 |

444 |

8-φ26 |

290 |

140 |

|

|

200 |

360 |

310 |

274 |

274 |

3 |

274 |

30 |

533 |

12-φ26 |

345 |

230 |

|

|

250 |

425 |

370 |

330 |

330 |

3 |

330 |

32 |

622 |

12-φ30 |

421 |

280 |

|

|

300 |

485 |

430 |

389 |

389 |

4 |

389 |

34 |

711 |

16-φ30 |

468 |

350 |

|

|

350 |

555 |

490 |

448 |

448 |

4 |

448 |

38 |

838 |

16-φ33 |

524 |

440 |

|

|

400 |

620 |

550 |

503 |

503 |

4 |

503 |

40 |

864 |

16-φ36 |

600 |

550 |

|

|

450 |

670 |

600 |

548 |

548 |

4 |

548 |

42 |

978 |

20-φ36 |

670 |

650 |

|

|

500 |

730 |

660 |

609 |

609 |

4 |

609 |

44 |

1016 |

20-φ36 |

750 |

750 |

|

|

4.0 |

100 |

235 |

190 |

156 |

150 |

3 |

3.5 |

24 |

356 |

8-φ22 |

270 |

80 |

|

125 |

270 |

220 |

184 |

176 |

3 |

3.5 |

26 |

400 |

8-φ26 |

280 |

115 |

|

|

150 |

300 |

250 |

211 |

204 |

3 |

3.5 |

28 |

444 |

8-φ26 |

290 |

150 |

|

|

200 |

375 |

320 |

284 |

260 |

3 |

3.5 |

34 |

533 |

12-φ30 |

345 |

240 |

|

|

250 |

450 |

385 |

345 |

313 |

3 |

3.5 |

38 |

622 |

12-φ33 |

412 |

290 |

|

|

300 |

515 |

450 |

409 |

364 |

4 |

3.5 |

42 |

711 |

16-φ33 |

468 |

360 |

|

|

350 |

580 |

510 |

465 |

422 |

4 |

4 |

46 |

838 |

16-φ36 |

524 |

450 |

|

|

400 |

660 |

585 |

535 |

474 |

4 |

4 |

50 |

864 |

16-φ39 |

600 |

560 |

|

|

450 |

685 |

610 |

560 |

524 |

4 |

4 |

50 |

978 |

20-φ39 |

670 |

660 |

|

|

500 |

755 |

670 |

615 |

576 |

4 |

4 |

52 |

1016 |

20-φ42 |

750 |

770 |

|

Product Inquiry

Leave your contact information to get the latest product discount information

Our Advantages

Rich experience

The company currently occupies 56,000 square meters of land with a building area of 18,000 square meters and has a history of over 20 years. Since its establishment in 1986, the company has cumulatively produced: over 1,600 kilometers of cast stone composite pipes; over 260,000 sets of flexible pipe joints; and over 18,000 units of various valves.

Production Capacity

Currently owns a single basalt cast stone production line with a production capacity of 15,000 tons/year and mechanical processing equipment with an annual output of 5,000 wear-resistant valves and 20,000 clamp-type flexible pipe joints.

Industry recognition

Products cover all provinces in China except Tibet and are exported to countries such as South Africa, Zimbabwe, Japan, India, Vietnam, and Australia.

Quality service

Our company has advanced technology and equipment, strong production capacity, and a complete quality assurance system. We have passed ISO9001 and ISO14001 certifications. We have currently obtained more than 20 invention patents and utility model patents and have won the title of "Shandong Star Enterprise of China Patents".